Level

3 schedules are the most used in planning. Level of schedule is usually

decomposed into 5. The intention of decomposing schedule level is to

manage and control the project or task to the manageable level.

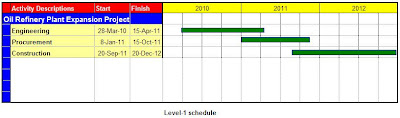

(1) Level 1 Schedule is the highest level, called overall project summary level.

It

includes major milestones or achievements, highlights major activities

and key deliverables. Especially, it is also used in progress reporting.

Established

by the client as an initial plan and can be integrated into level 2 and

level 3 schedules which involved sub contractor and vendors’ in puts

(commitments). Examples of level 1 element are

(a) Engineering, Procurement and Construction (For Oil refinery plant expansion project )

is

the area or system summary (roll up summary of level 3 schedule). It is

also called major summary schedule. It is used to integrate into level 3

and level 4 schedules which involved detail tasks. It can be used to

report the project area or trade progress status.

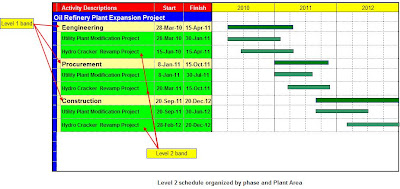

(2) Level 2 Schedule

(2) Level 2 Schedule

Examples of level 2 element are

(a) Utility Plant Modification Project, Hydro Cracker Revamp Work ( For Oil refinery plant expansion project)

(b) Furnace Area, Compressor Area Shutdown Work (For Chemical Plant Shutdown Work)

(3) Level 3 Schedule is a project coordinating and project reporting schedule. Roll up summary of level 4 schedule. It is a primary tool for the project status tracking and manpower loading analysis. It shows the summary of each discipline. For instance, piping engineering, mechanical engineering, civil/structure engineering, process engineering and electrical and instrumentation engineering are level 3 elements which are the disciplines of design engineering. Normally developed and established by EPC (engineering, procurement and construction) contractor. Used as a proposal schedule during the process of tendering. Also is used as a guide line for subcontractors and vendors for their bid submissions. Applied critical path method and used as monitoring schedule during the project execution phase. Normally, level 3 schedule represents the area of responsible manager such as engineering schedule by engineering manager, procurement by procurement manager and construction by construction manager. Can be integrated into level 4 and level 5 schedule. The 3 month look-ahead schedule is produced from this level and distribute to the responsible engineer or manager to plan ahead.

(4) Level 4 Schedule

is a low level schedule. It consists of the task or work categories to

be carried out. Level 3 schedule is further broken down into level 4 as

an execution schedule (working schedule). The detail task lists and work

sequence are shown in this level. Depending

on the nature of project, the level 4 schedule may be level 1 schedule

of subcontractor (and/or) vendors. For example, we have a new project

that required the new pump no- “P28” to be purchased and installed. Purchasing

of pump materials and manufacturing steps are apart of pump vendor’s

level 4 element. When the pump vendor’s schedule is roll-up into the

highest level , the time frame from the purchased order issued date to

deliver date at site, is level 1 element of vendor’s schedule. That

information becomes main contractor’s level 4 schedule input. 6

week look-ahead schedule, 3 week look-ahead schedule are frequently

produced form this schedule by filtering the time frame, and distribute

the responsible engineer or manger to plan ahead before getting close to

the targeted date.

(5) Level 5 schedule

is the lowest level of schedule. The task list and work sequence is

usually developed by the task supervisor or engineer and incorporated

into level 4 schedule to monitor day to day work.

.png)